Your practical guide for 20x20 aluminum profiles

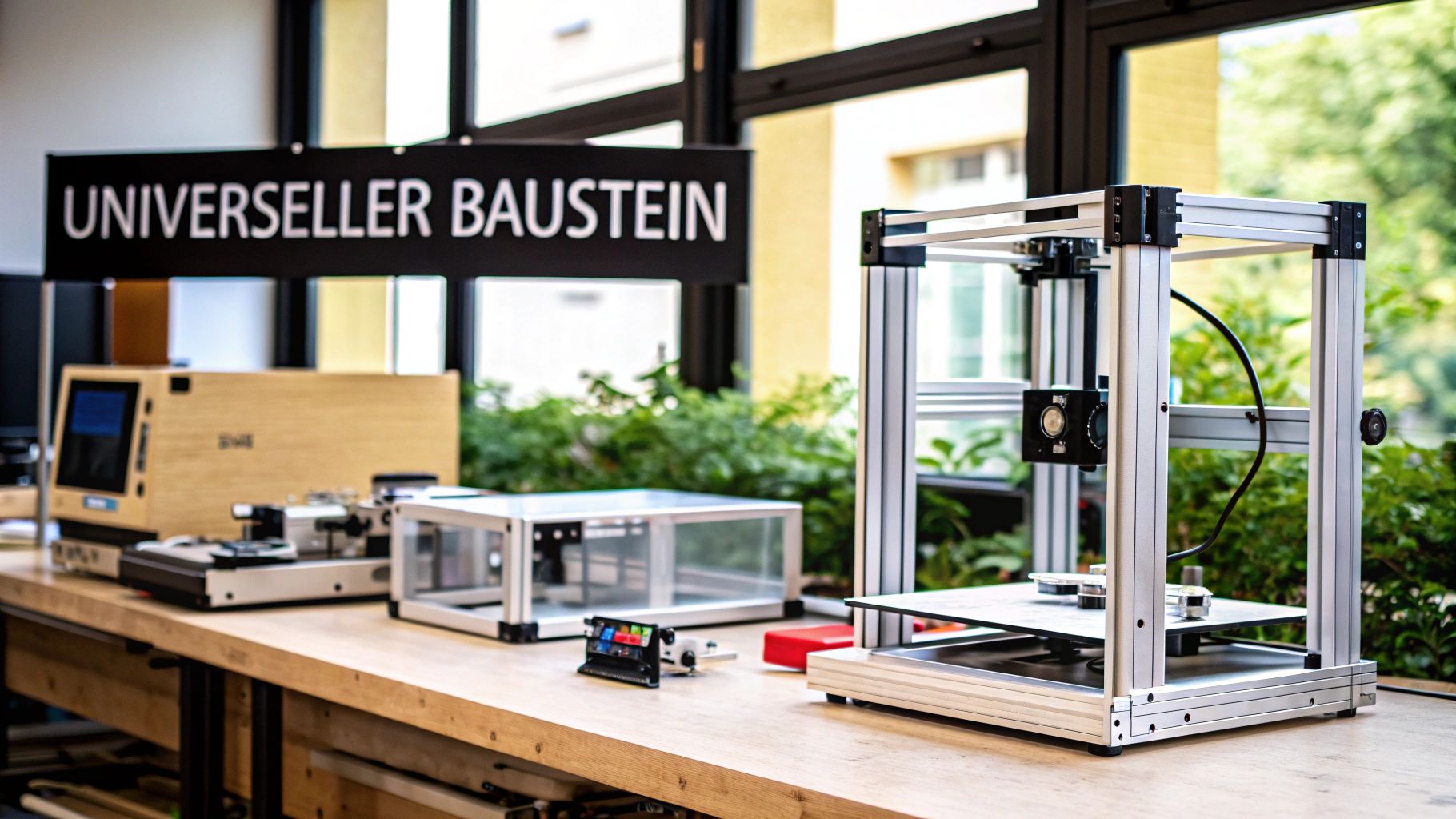

Mst. Stefan PrimusAnyone working in mechanical or plant engineering knows it: the 20x20 aluminum profile . You could almost call it the LEGO brick for professionals. Its enormous popularity is no accident – it perfectly combines low weight, high stability, and incredibly easy handling. This makes it the first choice for countless projects.

What makes the 20x20 aluminum profile so versatile?

Imagine building a stable machine frame, a delicate laboratory setup, or a flexible workstation – all with a single basic element. That's precisely the strength of the 20x20 aluminum profile. Its square base measuring 20 by 20 millimeters has established itself as an industry standard over the years. Why? Because it's the perfect compromise: compact enough for lightweight constructions, yet strong enough for load-bearing structures.

This versatility stems from three core characteristics that make all the difference in practice.

The perfect balance of stability and weight

Aluminum is naturally lightweight, but don't be fooled – it's extremely robust. A 20x20 profile offers remarkable bending and torsional stiffness, all while maintaining minimal weight. You'll notice this immediately during transport and assembly, where everything becomes much easier. At the same time, it reduces the overall mass of machines and equipment.

Especially in Austria, the 20x20 aluminum profile with a 5 mm groove has become the standard for modular building systems. It is usually manufactured from the alloy AlMgSi0.5 F25 , which is known for its excellent strength and corrosion resistance. Produced according to European standards, the highest quality is guaranteed. SPANNWERK.at is an established supplier of such system profiles, where you can find more information about the technical details.

Infinite modularity thanks to the slot system

The real genius behind this flexibility lies in the system of circumferential slots. These slots are the universal interface to which everything is attached. You can easily slide in and secure a huge selection of accessories such as T-nuts, connectors, and various attachments.

The beauty of it is that once built, nothing is set in stone. A structure made of aluminum profiles can be disassembled, expanded, or rebuilt for a completely new purpose at any time.

This feature makes the system not only extremely adaptable, but also surprisingly economical and sustainable. Instead of rebuilding everything when requirements change, you simply adapt the existing structure.

Natural corrosion resistance for a long service life

Aluminum has a built-in protective mechanism: In air, it forms a very thin but highly resistant oxide layer that protects it from corrosion. For even better protection and a higher-quality appearance, the profiles are often additionally anodized. The result is an extremely long service life, even in harsh industrial environments.

This reusability is a significant advantage, which we also examine in more detail in our article on sustainable assembly with reusable aluminum profiles . All these features combined make the 20x20 profile the versatile product it is today.

Choosing the right profile variants and surfaces

At first glance, many 20x20 aluminum profiles look deceptively similar. But the devil is in the details: the subtle differences in design, alloy, and surface treatment ultimately determine the success or failure of your project. Choosing the right profile is like choosing the right tool – it determines the stability, durability, and, not least, the appearance of the entire construction.

Before making a decision, it's worth taking a closer look at the basics. Each option has been developed for very specific requirements, from lightweight covers to heavy-duty machine frames. A wrong choice can not only impair functionality but often also incur unnecessary costs.

The core of the profile: the aluminum alloy

The foundation of any good structural profile is the aluminum alloy used. In practice, the EN AW-6063 T66 alloy has proven itself a true all-rounder. It strikes a balance between good mechanical strength and excellent machinability. In plain terms, this means the profiles are strong enough for most applications, yet can be easily sawn, drilled, and machined.

Another major advantage of this alloy is the excellent surface finish achievable after anodizing. This makes it the first choice for all applications where function and attractive appearance go hand in hand. With a specific weight of only around 0.49 kg per meter, the 20x20 aluminum profile is also remarkably lightweight, which significantly simplifies transport and installation.

Light, heavy or ultralight: finding the right design

The design, i.e., the internal structure of the profile, directly influences its weight and load-bearing capacity. In practice, a distinction is made between three main categories, each optimized for different purposes:

- Lightweight profiles (L-type): These are the standard profiles for the vast majority of applications. Perfect for frames, protective covers, or lightweight fixtures where a good compromise between stability and low weight is required.

- Heavy-duty profiles (S-type): These have more substance! This variant has thicker walls and more material in its core. It is always used when heavy loads need to be supported – for example, in machine frames or load-bearing structures.

- Ultra-lightweight profiles: These profiles have material reduced to an absolute minimum. They are ideal for weight-critical applications such as lightweight sliding doors or covers where virtually no forces are at work.

A simple principle from practical experience is: use as little material as necessary, but as much as required. A heavy profile for a simple protective cover is just as over-dimensioned as a lightweight profile for a load-bearing frame would be dangerously under-dimensioned.

While 20x20 profiles are mostly designed for lighter constructions with a 5 or 6 mm groove, larger cross-sections are of course available for more demanding projects. Take a look at the more robust category of aluminum profiles with an 8 mm groove to get a feel for how stability can be scaled.

The surface: from mill finish to colored coating

The surface of an aluminum profile is far more than just cosmetic – it's an important protective shield. Depending on environmental conditions and aesthetic requirements, various designs are available.

Press blank (raw)

This is, so to speak, the "naked" truth – the surface as it comes directly from the extrusion press. It's the most cost-effective option, but also more susceptible to scratches and corrosion, especially in humid environments. Ideal for internal structures that won't be visible later or that will be painted anyway.

Anodized (natural or black)

Anodizing artificially strengthens the natural oxide layer of aluminum. The result is a very hard, scratch-resistant, and corrosion-resistant surface. The naturally anodized finish, with its typical matte silver look, is the undisputed industry standard. Black anodized profiles have a particularly elegant appearance and reduce light reflections, making them attractive for applications in optics or exhibition stand construction, for example.

Powder-coated

When maximum design freedom and the highest level of protection are required, powder coating is the only way to go. Here, a colored powder is electrostatically applied and then baked on. This creates an extremely durable, impact-resistant surface that can be achieved in virtually any RAL color imaginable.

Correctly interpreting technical data and using it for stable constructions

A technical data sheet can seem quite daunting at first glance – a wall of numbers and abbreviations. But don't worry, you don't need to be an engineer to understand the key points. These values hold the key to building a structure that not only holds up but also remains stable over the long term.

Consider this data your personal tool. It tells you, even before the first cut, how a 20x20 aluminum profile will behave under load. Ignoring this data risks unsightly bending, vibration, or, in the worst case, even failure later on. With a little basic understanding, you'll make the right choice and build on safety from the start.

The key values for resilience

Imagine a simple wooden board laid across a stream. If you lay it flat, it will bend considerably even under light weight. But if you stand it upright, it suddenly becomes much more stable. This is precisely the principle behind the two most important parameters for aluminum profiles: the moment of inertia and the section modulus.

-

Moment of inertia (Ix and Iy): This value describes how stiff a profile is – that is, how well it resists bending. A higher moment of inertia simply means less deflection under load. This is the most important number when it comes to the stiffness of your structure.

-

Section modulus (Wx and Wy): This modulus indicates how much stress the profile can withstand before it permanently deforms or breaks. A higher value therefore signifies greater strength and load-bearing capacity.

This is anything but dry theory. For example, if you build a long shelf, a high moment of inertia ensures that the shelves remain perfectly straight even under load. Conversely, for a machine frame that is constantly subjected to vibrations, you need a high moment of resistance so that the structure can safely absorb the forces that occur.

An important point that is often forgotten: Stability depends heavily on the span. An aluminum profile measuring 20x20 mm that is rock-solid over a length of 500 mm can already bend noticeably over 2000 mm. This is precisely where the technical data helps to correctly assess such effects in advance.

The groove type: A small detail with a big impact

Besides the pure mechanics, there's one detail that's crucial in practice: the slot type. The slot is the universal interface where all connectors, T-nuts, and accessories are later attached. If you have the strongest profile but the wrong slot, nothing will fit in the end. Two variants have become established for 20x20 profiles:

- Groove 5: With a 5 mm groove width, this is the standard for lighter constructions. The matching accessories are usually somewhat more delicate and often also a bit cheaper.

- Slot 6: The 6 mm wide slot provides a more robust connection. Stronger T-nuts and connectors fit here, noticeably increasing the load-bearing capacity at the connection points.

The choice of groove determines the entire "ecosystem" of accessories available to you. Therefore, before purchasing, make absolutely sure that all profiles and connectors have the same groove type. This will save you a lot of trouble later.

Comparison of technical data of 20x20 aluminum profile variants

To save you time searching, we've compiled the typical values for the most common 20x20 profiles. This table will help you directly compare the profiles and quickly find the right one for your needs.

This table shows the most important mechanical properties and dimensions for common variants of the 20x20 profile to facilitate selection for specific load requirements.

| Profile variant | Weight (kg/m) | Groove type | Moment of inertia Ix/Iy (cm⁴) | Section modulus Wx/Wy (cm³) |

|---|---|---|---|---|

| Lightweight (Standard) | approximately 0.48 | Nut 5 / 6 | approximately 0.65 | approximately 0.65 |

| Difficult | approximately 0.60 | Nut 5 / 6 | approximately 0.75 | approximately 0.75 |

| Ultralight | approximately 0.35 | Nut 5 / 6 | approximately 0.50 | approximately 0.50 |

It's immediately apparent: even small differences in weight or moment make a significant difference to stability in practice. For a simple protective enclosure, the ultralight version is perfectly adequate. However, if you're planning a small, stable measuring table, the heavier version is the clearly better choice. Use this data to design your structure not only to be functional, but also material-efficient and, above all, safe.

Connection technology and accessories: How rods become a stable whole

A single profile is just a bar of metal. Only the right joining technique transforms it into a stable and functional structure. It's astonishing how quickly a basic framework can be assembled with a few brackets and the appropriate T-nuts.

But which accessories are really right for your 20x20 aluminum profile? Let's take a closer look at the options.

An overview of the most common connectors

For simple frames or structures that may not be intended to last forever, simple angle brackets are often the quickest and cheapest solution.

- Angle connectors: The classic. They allow you to precisely join two 20x20 aluminum profiles at a 90-degree angle . Simple, but effective.

- T-joints: If you need connections in three axes, i.e., want to build a T-junction, these joints are the first choice. They offer significantly more flexibility.

- Invisible connectors: For those for whom appearance is important. Here, the screws disappear inside the profile – perfect for a clean, professional finish.

If stability is paramount, many experienced users opt for robust corner connectors. These ensure maximum rigidity and leave virtually no room for movement in the structure.

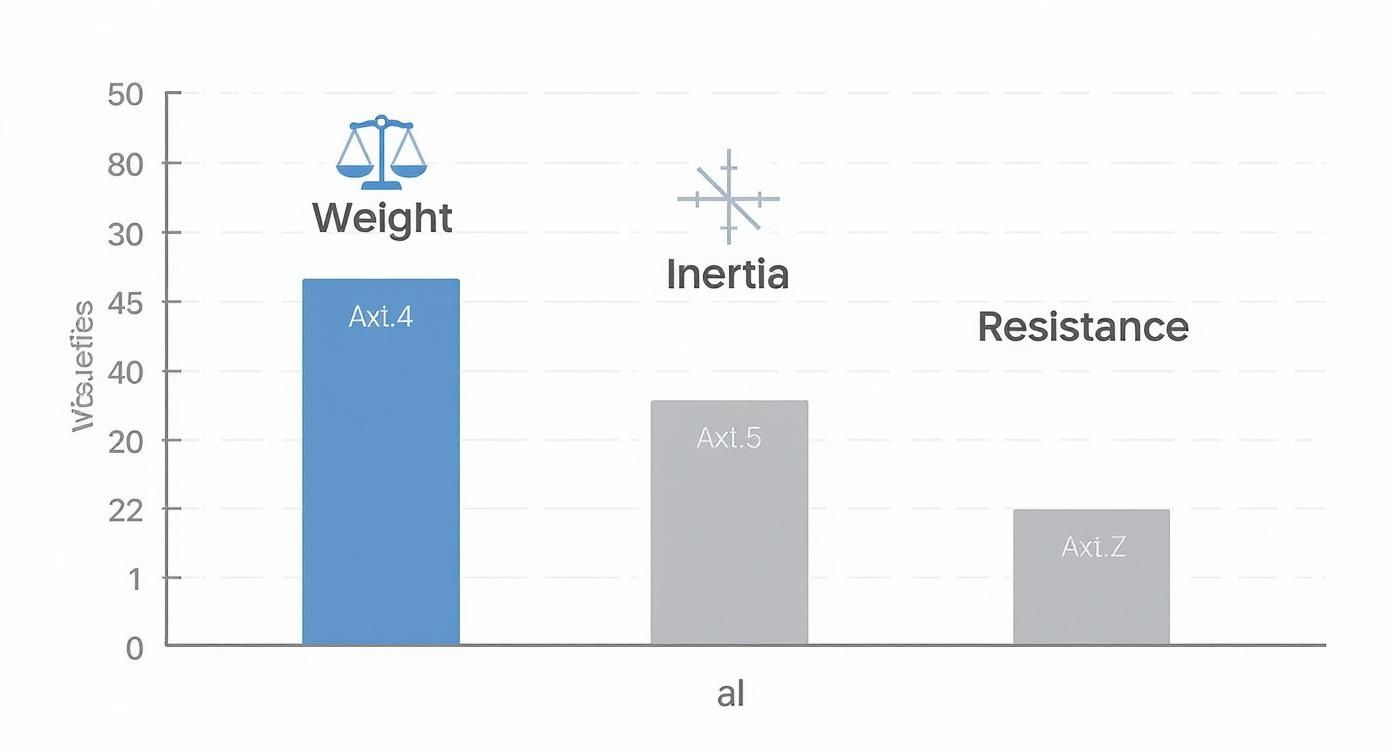

The following infographic provides a good overview of the key parameters that play a role in the 20x20 aluminum profile.

Here you can clearly see how weight, inertia and resistance moment are in a balanced relationship to each other, which makes the profile so versatile.

Selecting the right T-nuts – the be-all and end-all

T-nuts are the small but crucial helpers that securely anchor your connectors in the profile. The choice depends entirely on when and how you intend to use them.

- Swivel-in T-nuts: A real blessing when the frame is already assembled and you need to add something. They can be swiveled into the groove at any point afterward.

- Screw-in T-nuts: These often offer particularly high holding forces and are very cost-effective. They are pushed into the profile and then tightened.

- Standard T-nuts: The all-rounder. They are simply pushed into the profile from the end face and fit most common connectors.

So the most important question is: Do you need to remain flexible and be able to add parts later, or are you assembling everything from scratch?

Additional accessories that make the difference

Sometimes it's the little things that make a design go from "good" to "perfect".

- Cover caps: Not only do they look better, but they also protect the grooves from dust and dirt. A must for clean environments.

- Sealing profiles: Ideal for sealing gaps, damping vibrations or preventing the ingress of dust.

- Joints: If you need moving parts, for example for flaps or adjustable brackets, joints are indispensable.

You can find more detailed selection tips in our guide to aluminum connectors .

If nothing should be visible: Invisible screws

For trade fair construction, designer furniture, or laboratory equipment, where a flawless surface is essential, invisible screw connectors are the first choice. The entire fastening mechanism disappears inside the profile.

- Clamp connectors: Ingenious because they don't require pre-drilling. Assembly is quick and disassembly is just as easy.

- Heavy-duty connectors: For when things really need to withstand heavy loads. These connectors are designed for high forces and hold extremely securely.

- Press-fit connectors: These are permanently pressed into the groove and ensure an extremely stable, non-removable connection.

What you should pay attention to when buying

To ensure everything fits and holds up in the end, you should keep a few points in mind:

- Check the quality: Carefully examine the material quality and surface finish. Cheap products often end up being bought twice.

- Check the groove size: This is the most important thing! Make sure that profiles and all accessories have the same groove size (e.g., groove 5 or groove 6).

- Compare suppliers: Obtain quotes from retailers in Austria and Germany. Pay attention not only to the price, but also to delivery times and service.

For larger quantities, tiered pricing is often worthwhile. And ask about a cutting service – it saves time, hassle, and reduces waste.

Those who opt for high-quality connectors are investing in durability and safety. It's not an expense, but a safeguard.

From practice: Small details, big impact

In everyday life, it's often the little things that make all the difference. In laboratory shelving, invisible connectors ensure smooth, hygienic surfaces that are easy to clean. On machine enclosures, cover caps prevent chips and dust from accumulating in the grooves.

And with joints, adjustable protective flaps or lighting brackets can be implemented in workplaces in no time at all.

One last tip from a pro

Document your project!

- Create a simple bill of materials with item numbers and exact dimensions.

- Keep any leftover accessories well-organized.

If you ever need to expand or repair something later, you'll thank yourself. This way, your 20x20 aluminum profile project is perfectly set up not only today, but also in the future.

Practical examples and tips for assembly

Enough theory, now let's get down to brass tacks. In this section, we'll turn the planning into a tangible result. I'll show you how the versatile 20x20 aluminum profile is brought to life in real-world projects and what's truly important during processing and installation.

The true strength of this system lies in its simplicity and flexibility. Whether for rapid prototyping, a stable machine enclosure, or a customized workstation – the basic principles always remain the same. With the right techniques and a little care, even complex designs can be implemented cleanly and precisely.

Project example 1: Stable enclosure for a 3D printer

One of the most popular applications for the 20x20 aluminum profile is clearly the construction of enclosures for 3D printers. Such an enclosure not only protects against dust and drafts, which massively improves print quality, but also dampens operating noise and contains fumes.

For a typical cube measuring 600x600x600 mm, surprisingly little material is needed to get started.

-

Materials list:

- 12 x aluminum profile 20x20, length 560 mm (for the edges)

- 24 x angle brackets 20x20

- 48 x hammer nuts (matching the groove) and the corresponding screws

- Plexiglas or acrylic sheets for the walls

- Simple door hinges and a small magnetic closure

Assembly is incredibly simple: The profiles are screwed together with the angle brackets to form a stable cube. The side panels can then either be slid directly into the grooves or attached with special brackets. That's it.

Professional tips for proper processing

Precise processing of the profiles is half the battle for a result that not only functions but also looks good. Even if many retailers offer a cutting service, you often can't avoid making adjustments yourself on site.

Cut

A burr-free and perfectly square cut is essential. This is best achieved with a miter saw fitted with a blade designed for non-ferrous metals. Fine teeth ensure a truly clean cut edge without any fraying.

Drill

Always use a sharp HSS drill bit (high-speed steel). Pre-drill the hole to prevent the drill bit from wandering. To prevent the back side from splintering, clamp the profile firmly to a piece of scrap wood.

A simple but extremely effective tip from the workshop: A drop of cutting oil or alcohol while drilling cools the drill bit, extends its service life and ensures a significantly cleaner drill hole.

Thread cutting

For many connector types, threads need to be cut into the core holes of the profiles. Use a high-quality tap for this (e.g., M5 or M6, depending on the profile). To prevent seizing, it's best to work in three steps (roughing, intermediate, finishing tap) and always use cutting oil.

Project example 2: Modular workplace

Imagine a workbench that you can expand and adapt to new tasks at any time. With a base frame made of 20x20 aluminum profiles, this is no problem. The grooves serve as universal mounting rails for all sorts of things: tool holders, lighting, monitors, or additional storage surfaces.

The assembly follows a simple grid principle. You construct a basic frame for the tabletop and four legs. All connections are securely screwed together, ensuring high load-bearing capacity. And the best part: you can later add cross braces for additional shelves or privacy screens, exactly as you need.

Common assembly errors and how to avoid them

Even with such a user-friendly system, small errors can lead to instability or an unsightly appearance. Be aware of these common pitfalls, and everything will work perfectly from the start.

- Non-perpendicular cuts: A tiny deviation in the cutting, and the entire construction will end up crooked. Check every single cut with a precise angle.

- Incorrectly tightened screws: Screws should always be tightened by hand first, and then further tightened with care. Connections that are too loose will wobble, while screws that are too tight can damage the profile or connector.

- Forgotten T-nuts: The absolute classic! The frame is almost finished, and then you realize that a T-nut is missing for an important bracket. Plan the assembly steps beforehand or use swivel-fit T-nuts afterward. They can save the day.

Your shopping guide: How to cleverly procure 20x20 aluminum profiles

The project is ready, the plans are complete – but where do you get the right 20x20 aluminum profile without spending a fortune? The market is full of suppliers, but the differences are huge. The right choice depends entirely on your needs: Do you only need a few bars, or are you planning a whole series? Does everything have to be cut to the millimeter, or will you be doing the work yourself?

Procurement is thankfully not rocket science if you know what to look for. A well-chosen supplier not only ensures top quality but also saves you a lot of time and hassle in the long run.

Where is the best place to shop? A comparison

Basically, you have three options: the local retailer, the specialized online shop, or the familiar hardware store. Each option has its merits.

- Local specialist retailers: The clear advantage here is the personal consultation. You can handle the profiles, check the quality, and often receive some practical tips. The disadvantage: Prices are usually higher, and stock is often limited.

- Specialized online shops: For professionals and industrial users in Austria and Germany, this is often the best option. Here you'll find a huge selection, fair prices thanks to large order quantities, and often professional cutting services that take the work off your hands. Availability is usually excellent.

- DIY stores: A last resort for quick weekend needs or small quantities. However, the selection is very limited, lengths are fixed, and expert advice is largely a matter of luck.

A good specialist supplier combines the best of both worlds: the huge selection and good prices of a wholesaler with the expertise that you would otherwise only get locally.

Your checklist for a smooth ordering process

To ensure your order goes smoothly and you receive exactly the materials you need for your project, a simple checklist will help. These few points will save you from costly mistakes and reorders.

- Specify precise dimensions and tolerances: Don't just state the length. Also define the tolerance that is acceptable to you (e.g., +/- 0.5 mm ).

- Define the surface finish: Do you need the profiles mill finish for your own painting, classically anodized , or powder-coated in a special color?

- Check the groove type: It sounds trivial, but it's crucial. Make sure that all profiles and accessories fit the same groove (e.g., groove 5 ).

- Order accessories at the same time: Think of everything – connectors, T-nuts, the matching screws and the cover caps for a clean finish.

- Use the cutting service: Does the retailer offer a precise cutting service? This saves you a lot of time and effort on site and ensures perfectly fitting parts.

A good overview of different aluminum profiles and the matching accessories greatly simplifies the planning process. You can find such comprehensive overviews directly from suppliers like SPANNWERK.at .

Save costs, but not on quality

Shopping smartly doesn't mean automatically going for the cheapest offer. With a few tricks, you can save money without compromising on quality.

If you have the option to cut the material yourself, buy standard lengths like 1000 mm or 2000 mm . These are often significantly cheaper than custom cuts. For larger projects, it's always worth asking about quantity discounts or tiered pricing. Another tip: Many retailers sell offcuts from custom cuts at heavily reduced prices – perfect for smaller components or testing.

Your questions about the 20x20 aluminum profile – answered briefly and concisely

Here I have compiled the most frequently asked questions that I encounter in practice regarding the 20x20 aluminum profile . Consider this section a short cheat sheet to help you make the right decisions for your project.

What load can a 20x20 aluminum profile actually bear?

That's the crucial question, and the honest answer is: it depends. There's no general weight limit in kilograms, because the load-bearing capacity always depends on three things: the span (i.e., the distance between the supports), the type of fastening, and of course the profile type itself (lightweight, heavyweight).

A short piece of profile, securely screwed at both ends, can withstand a surprisingly large amount of weight. In contrast, a long profile, supported only at the ends, will visibly bend even under a light load.

As a rule of thumb: the shorter the free length and the stiffer the connection, the greater the load it can bear. For precise calculations, a look at the technical data sheet is essential. The values for moment of inertia and section modulus are the crucial parameters for an exact calculation.

What does "Nut 5" or "Nut 6" actually mean?

The groove is the characteristic groove on the sides of the profile. The number following it is simply the width of this groove in millimeters .

- Groove 5: Here the groove is 5 mm wide. This is often found in very light, delicate constructions.

- Slot 6: A 6 mm wide slot. This is the common standard for the 20x20 profile and offers the widest selection of accessories such as T-nuts and connectors. The connection is also somewhat more robust here.

Important: The groove size defines the entire system. Therefore, ensure meticulously that profiles, connectors, and all attachments have the same groove; otherwise, nothing will fit together in the end.

Can I cut and drill the profiles myself?

Yes, absolutely. That's one of the great advantages of this modular system. But to ensure the result looks professional, you need the right tools.

For a clean, burr-free cut, it's best to use a miter saw with a blade designed for non-ferrous metals (often labeled "non-ferrous metal" blade). Sharp HSS drill bits work perfectly for drilling. A little tip from the workshop: A drop of cutting oil or rubbing alcohol cools the workpiece, makes drilling easier, and ensures a perfectly clean hole.

How do I connect two profiles most securely?

The stability of a connection depends entirely on the connector. When maximum strength is truly essential, screw connectors that are screwed directly into the core hole of the profile are hard to beat. They create a force-fit and form-fit connection that can withstand enormous forces.

Simple angle brackets are quick to assemble and perfectly adequate for many standard frames, but they are not as rigid against torsional forces. If aesthetics are a major concern and no brackets should be visible, then invisible clamp connectors are the most elegant solution.

Ready to tackle your project with industrial-grade components? At SPANNWERK.at you'll find a huge selection of aluminum profiles, connectors, and all the accessories you need. Browse our range and find the perfect material for your construction: https://spannwerk.at

Article created using Outrank